Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the realm of precision machining and fabrication, the role of the Carbide Burr Tool is indispensable. As industries continue to evolve, the demand for high-efficiency tools that can facilitate intricate designs and fine finishes has surged. According to a report by Research and Markets, the global market for rotary tools, including carbide burrs, is anticipated to witness a compound annual growth rate (CAGR) of 4.5% from 2020 to 2025. This growth can be attributed to the increasing adoption of advanced manufacturing technologies across sectors such as aerospace, automotive, and metalworking.

Carbide burr tools are favored for their durability and performance, often outperforming traditional steel tools in terms of cutting efficiency and lifespan. Industry data indicates that using carbide burrs can enhance productivity by up to 30%, providing a clear advantage in competitive markets where precision and time management are critical. As we delve into the selection and effective use of carbide burr tools, understanding their capabilities, applications, and proper techniques will empower users to leverage these tools for optimum results, ensuring they remain at the forefront of innovation in their respective fields.

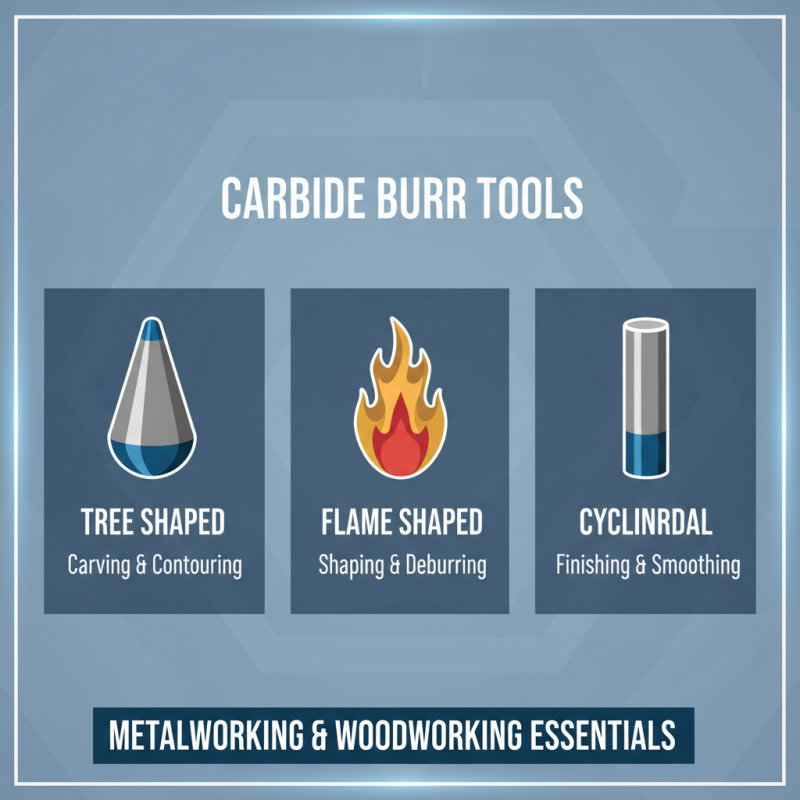

Carbide burr tools are essential in various applications, especially in metalworking and woodworking. These tools come in diverse shapes and sizes, each designed for specific tasks. The most common types include tree-shaped, flame-shaped, and cylindrical burrs, which are used for tasks ranging from carving and shaping to deburring and finishing surfaces. Understanding the unique characteristics of each type is crucial for achieving optimal results in any project.

In addition to their shapes, carbide burr tools can also be classified based on their cutting performance. For instance, some burrs have coarse cuts ideal for rapid material removal, while others possess fine cuts designed for detailed work and smooth finishes. The choice of burr should align with the material being worked on—harder materials may require more robust burrs to withstand wear and tear. Properly matching the tool to the application not only enhances efficiency but also extends the tool's lifespan, making it a valuable investment for professionals and hobbyists alike.

When selecting carbide burr tools, several key factors come into play to ensure optimal performance and efficiency in various applications. One crucial aspect is the type of material being machined. Carbide burrs are available in different shapes and sizes, including cylindrical, flame, and ball shapes, each designed for specific tasks. According to a market analysis report by Grand View Research, the global carbide bur market is expected to grow by over 5% annually, with increased demand in aerospace and automotive sectors, indicating the importance of choosing the right tool for the material at hand.

Another significant aspect is the burr's grit and cutting edge. The grit size determines the smoothness of the finish, with finer grits providing a polished look suitable for aesthetic applications, while coarser grits are better for heavy material removal. Furthermore, experts suggest considering the burr's shank size, as it needs to fit the rotary tool correctly to avoid vibrations that can lead to inaccurate cuts and reduced tool life. A comprehensive study by the International Journal of Machine Tools and Manufacture highlights that using the proper carbide burr not only enhances precision but can also increase productivity by up to 40%, emphasizing that informed decisions during the selection process can significantly affect outcomes in machining operations.

When using carbide burr tools, understanding the right techniques can significantly enhance your performance and results. One effective approach is to choose the appropriate burr shape and size for your specific application. For instance, a pointed burr may be suited for intricate detailing, while a flat burr can be utilized for material removal on larger surfaces. Additionally, maintain the proper angle and pressure while working; applying too much pressure can lead to tool damage and uneven finishes. It's also essential to keep the burr at a consistent speed, as varying the speed can affect the quality of the work.

Another crucial technique is to develop a steady hand and control over the tool's movement. Using smooth, fluid motions will not only improve precision but also extend the life of the burr. It's advisable to practice on scrap material to refine your skills before moving on to actual projects. Moreover, regular cleaning of the burr is vital to prevent buildup of debris which can interfere with performance. Finally, ensure you wear appropriate safety gear, including goggles and masks, to protect yourself from dust and debris generated during the cutting process. By mastering these techniques, you can maximize the efficiency and effectiveness of your carbide burr tools.

To ensure the longevity of your carbide burr tools, proper maintenance is crucial. One of the most essential tips is to clean the burrs after each use. Debris, dust, and material buildup can significantly reduce the effectiveness of the tool over time. Using a brush or compressed air can help remove particles that may cling to the burr, keeping it sharp and ready for the next task.

Another key maintenance tip is to store carbide burr tools in a dry, organized manner. Moisture can lead to rust, while rough handling might cause physical damage. Utilizing a dedicated storage case or drawer allows you to keep your tools protected from potential harm. Additionally, keeping your tools separated will prevent accidental dulling from contact with other tools.

Finally, regularly inspecting your carbide burr tools for signs of wear can help you catch any potential issues before they become significant problems. Look for chips or gradual loss of sharpness, and replace any tooling that no longer performs effectively. Staying vigilant will not only prolong the life of your tools but also maintain the quality of your work.

When using carbide burr tools, safety should always be the top priority. These tools are designed to remove material quickly and efficiently, but they can also pose significant risks if not handled properly. It's essential to wear appropriate personal protective equipment (PPE) such as safety goggles to protect your eyes from flying debris, and gloves to reduce the risk of cuts. A dust mask or respirator is important as well, especially when working with materials that can generate harmful dust. Keeping your work area clean and well-lit can also minimize accidents and improve visibility while you'll be using the tools.

In addition to personal safety gear, ensuring that your workspace is organized can further enhance safety. It's advisable to keep other tools and loose materials out of the immediate area while operating carbide burrs, as distractions can lead to mishaps. Furthermore, securing the workpiece firmly to prevent movement will help maintain control while using the burrs. Always follow the manufacturer's guidelines for usage and maintenance; failure to do so can not only jeopardize your safety but also damage the tool itself. Regularly inspect your carbide burrs for wear and replace them as needed to ensure optimal performance without compromising your well-being.

| Tool Type | Recommended Use | Safety Precautions | Maintenance Tips |

|---|---|---|---|

| Tapered Burr | Ideal for contouring and shaping materials. | Always wear safety goggles and a dust mask. | Clean after use and store in a dry place. |

| Ball Nose Burr | Used for radius cuts and hollow shapes. | Ensure work area is well-ventilated. | Inspect for wear regularly. |

| Cylinder Burr | Perfect for flat surfaces and square corners. | Never exceed recommended RPM. | Lubricate as necessary to improve performance. |

| Flame Burr | Used for finishing and deburring. | Keep flammable materials away from the work area. | Store in a case to avoid damage. |