Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In recent years, the demand for advanced materials in the engineering sector has surged, driven by the need for high-performance components that can withstand extreme conditions. Tungsten Alloy, known for its exceptional density, strength, and thermal stability, has emerged as a vital material in various applications, from aerospace to medical equipment. According to a report by Research and Markets, the global tungsten alloy market is expected to grow significantly, reaching USD 1.8 billion by 2026, at a CAGR of 6.5% from 2021 to 2026. This growth is primarily attributed to the increasing adoption of tungsten alloy components in nuclear applications, radiation shielding, and precision machining. The ability of tungsten alloy to maintain structural integrity at high temperatures while providing substantial weight savings makes it an essential choice in modern engineering. Understanding the benefits and applications of Tungsten Alloy not only highlights its versatility but also underscores its critical role in advancing technology across various industries.

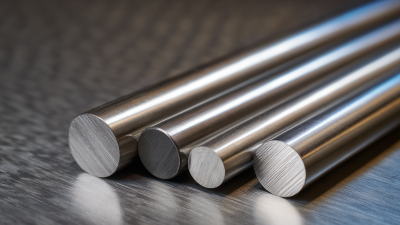

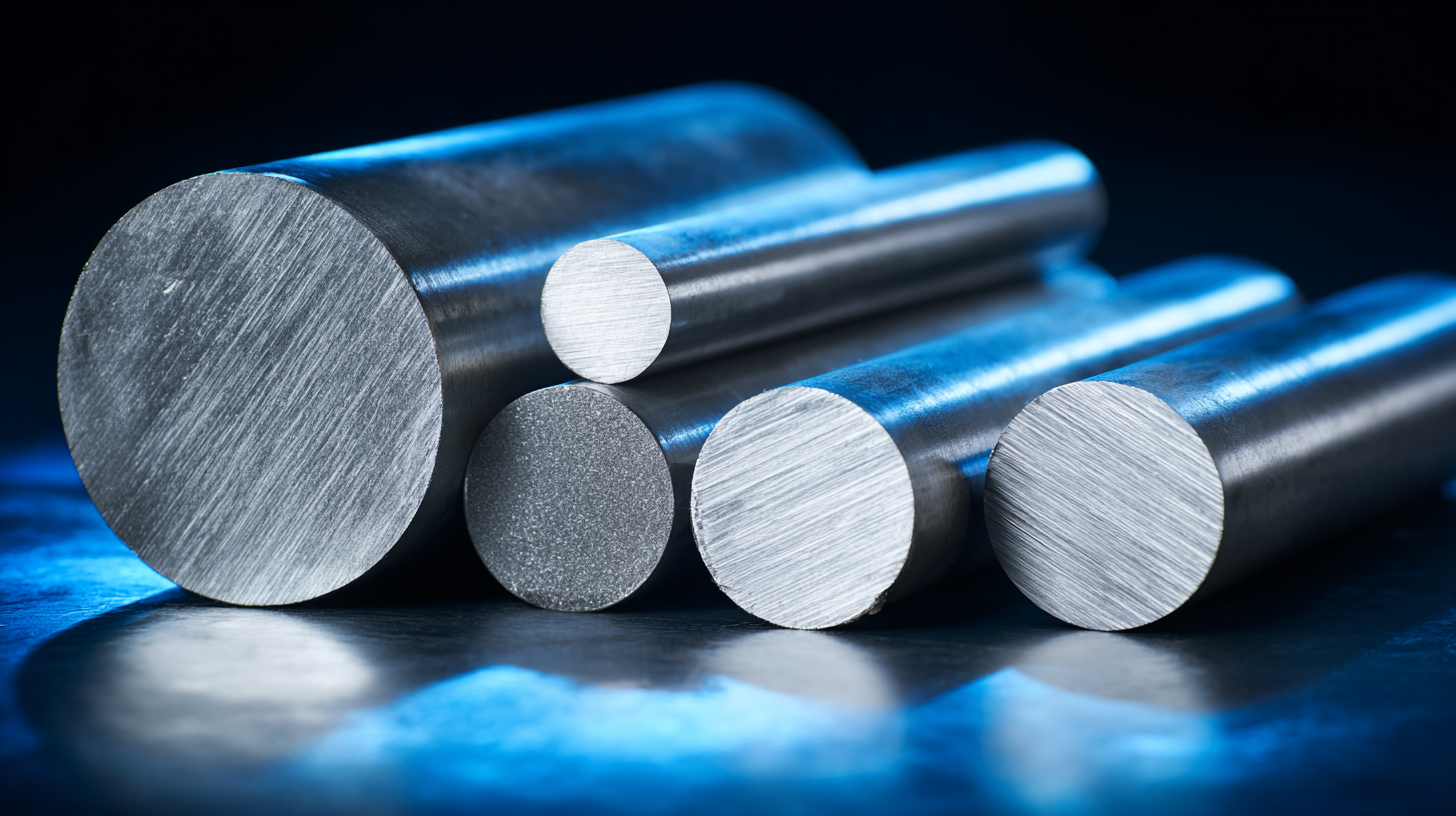

Tungsten alloy has emerged as an essential material in modern engineering due to its superior density and strength. With a density nearly twice that of lead, tungsten alloy provides weight advantages that are critical in applications where space and weight constraints are paramount, such as aerospace and automotive engineering. This high density translates into enhanced stability and balance in various components, making tungsten alloy an ideal choice for counterweights in aircraft and balancing systems in heavy machinery.

Moreover, the impressive strength of tungsten alloy significantly contributes to its versatility across various engineering applications. Remarkably resistant to wear and deformation, tungsten alloy outperforms many traditional materials in challenging conditions. This durability allows for extended lifespans of components, leading to reduced maintenance costs and improved operational efficiency. Engineers often utilize tungsten alloys in tooling, radiation shielding, and specialized equipment that demands materials capable of withstanding high stress and extreme environments. The unique properties of tungsten alloy not only optimize performance but also open new opportunities for innovation in engineering design.

Tungsten alloy has gained significant attention in aerospace and military industries due to its unique properties that enhance performance in demanding applications. As a crucial raw material, tungsten enables the creation of high-performance components that withstand extreme conditions. Recent insights indicate that the global tungsten carbide market is projected to grow significantly, with an anticipated CAGR of 4.4% leading up to 2033. This growth reflects the increasing demand for tungsten alloys in key end-use industries, including aerospace and defense, where materials need to exhibit exceptional strength and durability.

Tungsten alloy has gained significant attention in aerospace and military industries due to its unique properties that enhance performance in demanding applications. As a crucial raw material, tungsten enables the creation of high-performance components that withstand extreme conditions. Recent insights indicate that the global tungsten carbide market is projected to grow significantly, with an anticipated CAGR of 4.4% leading up to 2033. This growth reflects the increasing demand for tungsten alloys in key end-use industries, including aerospace and defense, where materials need to exhibit exceptional strength and durability.

In the realm of military technologies, tungsten's critical role is underscored by its outstanding ballistic and mechanical properties. Innovations in manufacturing techniques, such as 3D printing tungsten alloys through powder bed fusion (PBF), are paving the way for more efficient production methods that are reshaping high-performance applications. The integration of these alloys not only ensures improved performance in armored vehicles but also addresses the challenges posed by evolving military strategies. With the rising demand and tight supply, driven by geopolitical factors, tungsten has emerged as a strategic metal that underpins advancements in defense and technological sectors.

Tungsten alloy plays a pivotal role in radiation shielding, particularly within the medical and nuclear sectors. Due to its high density and effective attenuation properties, tungsten alloy is an essential material in the construction of radiation shielding devices. According to the National Council on Radiation Protection and Measurements (NCRP), materials with high atomic numbers, such as tungsten, are particularly effective for handling gamma and X-ray radiation, making them invaluable in both diagnostic imaging and radiation therapy.

In medical applications, tungsten alloy is frequently used in the design of protective shields for radiotherapy machines and diagnostic imaging equipment. A report from the World Health Organization (WHO) indicates that the demand for advanced radiation therapy techniques has surged globally, necessitating more efficient shielding materials. Likewise, in nuclear facilities, tungsten's robustness and substantial shielding capability contribute to the safety of operations, minimizing radiation exposure to both workers and the surrounding environment. The Global Nuclear Fuel Cycle Report by the International Atomic Energy Agency (IAEA) emphasizes the importance of using high-density materials like tungsten alloy in maintaining safety standards within nuclear reactors and waste management protocols.

This chart illustrates the distribution of various applications of tungsten alloy in radiation shielding across different fields, highlighting its significance in medical imaging, radiation therapy, and other key areas.

Tungsten alloy has emerged as a key player in modern engineering, particularly in manufacturing processes where cost-effectiveness is crucial. Compared to traditional materials like steel or aluminum, tungsten alloy exhibits superior density and strength, which translates to reduced material usage and consequently lower production costs. For industries that prioritize durability and weight efficiency, switching to tungsten alloy can lead to significant savings over time, despite its initial higher material price.

Tungsten alloy has emerged as a key player in modern engineering, particularly in manufacturing processes where cost-effectiveness is crucial. Compared to traditional materials like steel or aluminum, tungsten alloy exhibits superior density and strength, which translates to reduced material usage and consequently lower production costs. For industries that prioritize durability and weight efficiency, switching to tungsten alloy can lead to significant savings over time, despite its initial higher material price.

Tip: When considering materials for your next engineering project, evaluate not only the upfront costs but also the longevity and maintenance requirements of the materials. Tungsten alloy’s resilience often means less frequent replacements and repairs, which can offset higher initial costs.

The versatility of tungsten alloy extends across various applications, from aerospace to military hardware, where reliability is paramount. As organizations strive for enhanced performance with minimized expenditures, tungsten alloy presents a viable alternative, enabling engineers to engineer products that withstand extreme conditions without compromising on budget.

Tip: Conduct a cost-benefit analysis when assessing new material options. Including factors such as lifecycle longevity and performance under stress can provide a clearer picture of the value that tungsten alloy brings to your project compared to conventional alternatives.

The future of tungsten alloy development is set to reshape various engineering sectors, particularly due to its remarkable properties such as high density, excellent thermal conductivity, and resistance to wear and corrosion. According to a report by Market Research Future, the global tungsten alloy market is projected to grow significantly, reaching approximately USD 1.75 billion by 2025. This growth is driven by increasing applications in aerospace, military, and medical industries, where precision and durability are paramount.

As the demand for advanced materials continues to escalate, innovations in tungsten alloys are focusing on enhancing their mechanical properties and reducing costs. Emerging trends include the development of nano-structured tungsten alloys, which exhibit superior strength and flexibility. These innovations are not only poised to enhance the performance of engineering components but also contribute to sustainability within the industry by optimizing resource usage.

TIP: When considering tungsten alloys for specific applications, always assess their compatibility with other materials and the specific environmental conditions of intended use. Additionally, keep an eye on ongoing research in this field, as new methodologies may lead to breakthroughs that can further elevate the performance and cost-effectiveness of tungsten alloys.

| Application | Benefit | Future Trend | Impact on Engineering |

|---|---|---|---|

| Aerospace Components | High density for weight reduction | Increased use of advanced alloys | Improved fuel efficiency |

| Medical Devices | Radiation shielding | Development of bio-compatible alloys | Enhanced safety in medical procedures |

| Defense Applications | High penetration capabilities | Integration with composite materials | Increased effectiveness of military equipment |

| Industrial Machinery | Wear resistance and longevity | Sustainability measures in production | Lower operational costs |

| Sports Equipment | Enhanced performance with lower weight | Innovations in design techniques | Improved user experience and outcomes |