Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

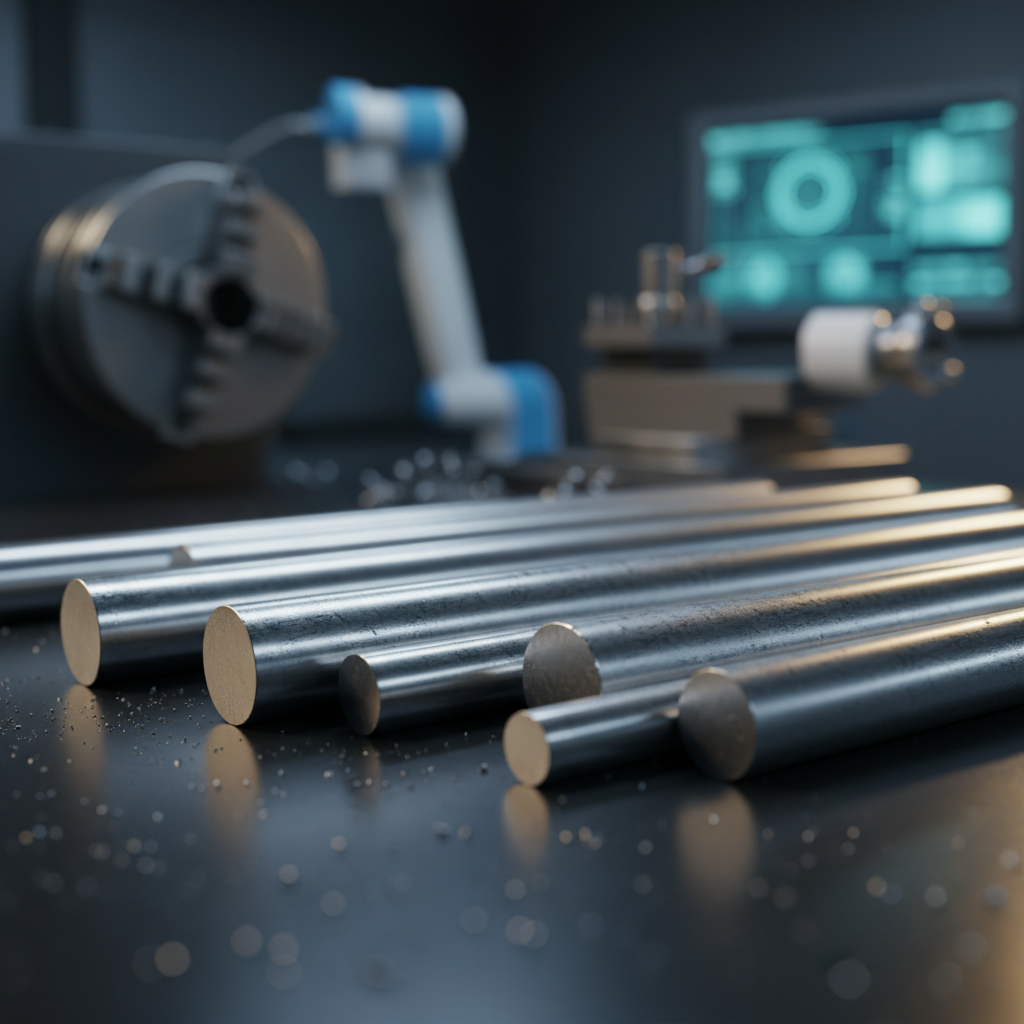

In the realm of advanced materials, the significance of Tungsten Metal Rods has been increasingly recognized in various industrial applications. According to a recent report by the Global Tungsten Industry Association, the demand for tungsten products is projected to grow by 6.2% annually, driven by the expanding aerospace and manufacturing sectors. Experts agree that the unique properties of tungsten, such as its high density, exceptional hardness, and impressive corrosion resistance, make it an indispensable material for high-performance applications.

Dr. Emily Chen, a leading expert in materials science, emphasizes the increasing importance of selecting the right Tungsten Metal Rod for specific applications: "The performance of tools and components often hinges on the material's properties; a carefully chosen tungsten rod can significantly enhance durability and efficiency." With a myriad of options available in the market, understanding the key characteristics and benefits of these products is vital for professionals looking to optimize their operational capabilities.

Dr. Emily Chen, a leading expert in materials science, emphasizes the increasing importance of selecting the right Tungsten Metal Rod for specific applications: "The performance of tools and components often hinges on the material's properties; a carefully chosen tungsten rod can significantly enhance durability and efficiency." With a myriad of options available in the market, understanding the key characteristics and benefits of these products is vital for professionals looking to optimize their operational capabilities.

As we delve into the top picks for Tungsten Metal Rods in 2025, we will explore their performance metrics and durability, equipping you with the knowledge necessary to make informed decisions for your projects. Whether for cutting, machining, or other specialized functions, selecting the right tungsten rod can make all the difference in achieving superior results.

Tungsten metal rods have become increasingly popular in various industrial applications due to their exceptional durability and performance characteristics. One of the notable advantages of tungsten is its high density, which is approximately 19.3 g/cm³, making it one of the heaviest and strongest metals available. This property allows tungsten rods to withstand extreme conditions such as high temperatures and pressures, which are commonly found in aerospace, military, and manufacturing industries. According to a recent report from the Global Tungsten Market Analysis, the demand for tungsten materials is projected to grow by 4.2% annually through 2026, underscoring its critical role in modern engineering solutions.

In addition to their superior physical properties, tungsten metal rods offer excellent resistance to wear and corrosion. This makes them ideal for applications involving heavy wear, such as in cutting tools, dies, and industrial machinery. The 2022 Industrial Materials Review indicated that tungsten rods outperform other materials in terms of lifespan and reliability, reducing maintenance costs and downtime for businesses. Furthermore, their ability to maintain integrity at high temperatures makes them suitable for use in high-performance environments, including turbines and reactors, solidifying their importance in sectors where material failure is not an option.

When selecting high-quality tungsten metal rods, several key performance metrics should be considered to ensure durability and optimal performance. First, the density of the tungsten rod is crucial; with a high density, these rods provide better resistance to wear and deformation, making them suitable for high-impact applications. Typically, tungsten rods range from 17 to 19 g/cm³, and higher densities often indicate better quality and resilience.

Another vital metric is the material purity. Tungsten rods with higher purity levels, ideally over 99.5%, tend to exhibit superior mechanical properties, such as enhanced strength and tensile strength at elevated temperatures. Additionally, surface finish and dimensional tolerances play a significant role in the rod’s performance, especially in precision machining applications. Smooth finishes reduce friction and wear, while tight tolerances ensure compatibility with tooling and enhance overall efficiency in operational settings. By carefully evaluating these metrics, users can select the best tungsten rods that meet their specific needs.

| Rod Type | Diameter (mm) | Length (mm) | Density (g/cm³) | Tensile Strength (MPa) | Melting Point (°C) | Price (USD) |

|---|---|---|---|---|---|---|

| Standard Tungsten Rod | 10 | 1000 | 19.3 | 1510 | 3422 | 150 |

| High Purity Tungsten Rod | 12 | 750 | 19.25 | 1430 | 3422 | 200 |

| Alloyed Tungsten Rod | 8 | 500 | 18.5 | 1350 | 3000 | 120 |

When evaluating tungsten metal rods in 2025, strength, weight, and cost efficiency emerge as key factors that influence consumer choice. Tungsten rods are renowned for their remarkable tensile strength, which makes them ideal for high-stress applications in various industries. When comparing options, it's crucial to look at the specific tensile strength ratings of each product, as some rods offer enhanced durability, allowing for extended use in demanding environments.

Weight is another significant consideration; tungsten is one of the densest metals available, which can be both an advantage and a disadvantage depending on the application. Heavier rods may provide stability in certain contexts, while lighter options can enhance maneuverability. Furthermore, evaluating cost efficiency is essential. While higher-priced tungsten rods often promise superior performance and durability, it's vital to analyze the cost-per-use over time to determine long-term value. A balanced approach, considering the interplay between strength, weight, and cost, will help individuals and businesses select the right tungsten metal rods tailored to their specific needs.

When assessing the durability of tungsten metal rods, it's essential to consider the rigorous testing standards they must undergo, particularly in extreme conditions. These standards often include high-temperature exposure, corrosion resistance, and mechanical stress tests, which simulate real-world applications where these rods are commonly used. By subjecting tungsten rods to varying degrees of heat and harsh environments, manufacturers can better understand their performance limits and lifespan.

Additionally, factors such as impact resistance and fatigue under cyclic loading play a crucial role in evaluating the overall durability of tungsten rods. The testing process typically involves advanced methodologies, including tensile strength evaluations and bend tests, ensuring the rods can withstand not only static loads but also dynamic forces that might occur during usage. These comprehensive evaluations are critical for industries where reliability is paramount, making sure that the chosen tungsten metal rods can deliver superior performance even under the most demanding conditions.

This chart represents the durability scores of various tungsten metal rods tested under extreme conditions. The scores are based on five key performance indicators: Tensile Strength, Hardness, Corrosion Resistance, Heat Resistance, and Impact Resistance.

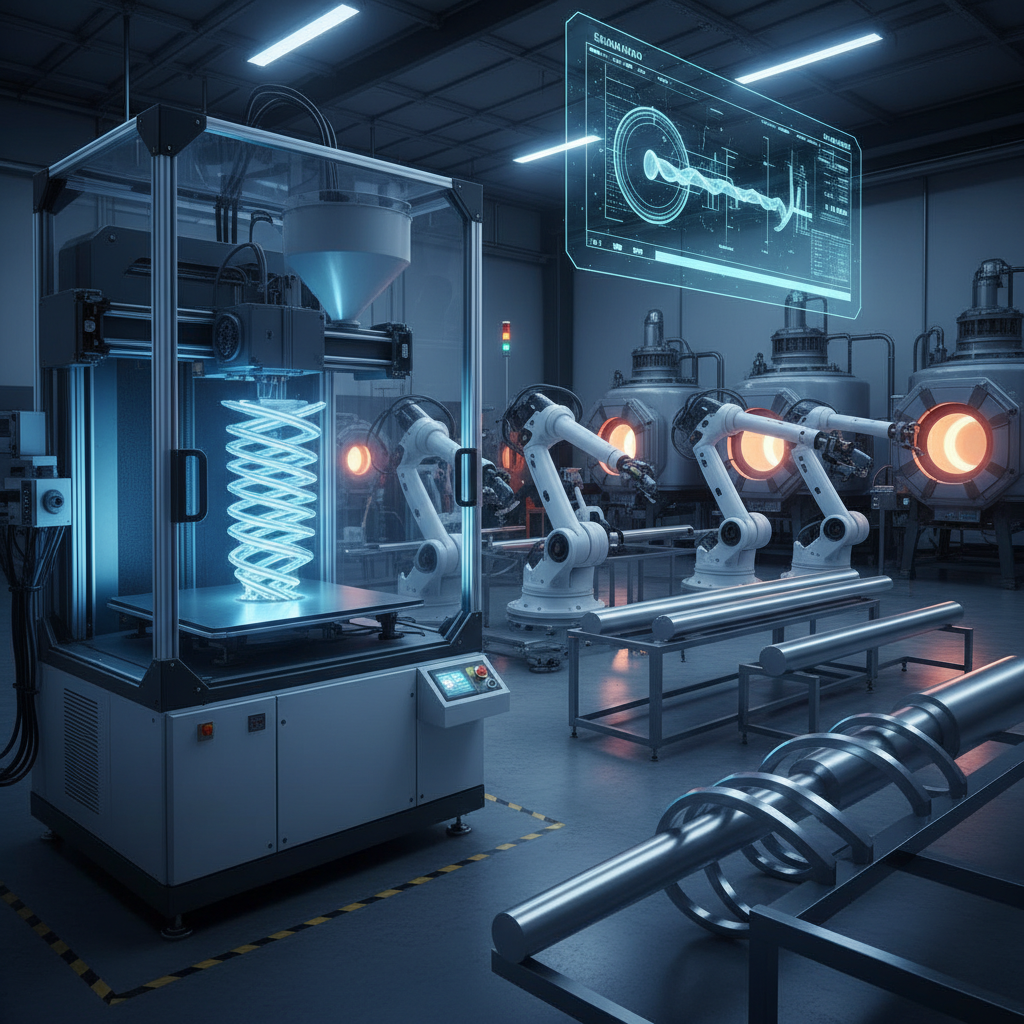

The tungsten metal rod manufacturing industry is experiencing significant advancements due to cutting-edge technologies and innovative techniques. One of the most notable trends is the integration of additive manufacturing, commonly known as 3D printing. This approach allows for more complex geometries and reduced material waste, enabling manufacturers to produce rods that meet specific performance requirements with enhanced precision. The ability to customize tungsten rods for various applications, from aerospace to medical devices, showcases how technology is revolutionizing traditional manufacturing processes.

Additionally, advancements in alloying techniques have improved the mechanical properties of tungsten rods. Manufacturers are now able to create rods that maintain high density while enhancing strength and corrosion resistance. This has been pivotal in applications that require materials to withstand extreme environments, such as in high-temperature furnaces or radiation shielding. Furthermore, ongoing research into nanostructured tungsten materials promises to unveil even greater performance enhancements, paving the way for a new generation of tungsten rods that push the boundaries of durability and efficiency in demanding applications.