Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In today's competitive manufacturing landscape, the drive for increased efficiency and tool longevity is paramount. Cemented carbide, a composite material known for its exceptional hardness and wear resistance, plays a crucial role in revolutionizing various industries, including aerospace, automotive, and metalworking. According to a recent report by MarketsandMarkets, the global cemented carbide market is expected to reach USD 32.5 billion by 2026, growing at a CAGR of 5.8%. This growth is largely attributed to the rising demand for cutting tools that can withstand extreme conditions while maintaining performance. As manufacturing companies strive to enhance productivity and reduce operational costs, the adoption of cemented carbide tools is becoming more prevalent. The unparalleled durability of cemented carbide not only extends tool life but also minimizes downtime, thus significantly impacting overall manufacturing efficiency.

The evolution of cemented carbide in modern manufacturing processes is driven by its exceptional properties, offering significant advantages over traditional materials. As industries push for increased efficiency and tool longevity, cemented carbide has become a pivotal component in advanced manufacturing techniques. This composite material, primarily made of tungsten carbide and cobalt, exhibits remarkable hardness and wear resistance, making it ideal for cutting tools and machining applications. Recent studies indicate that the microstructure of cemented carbide substrates plays a crucial role in enhancing the performance of coatings, such as AlTiSiN, which further increases the lifespan and reliability of these tools during dry machining of demanding materials like titanium alloys.

In addition to its manufacturing prowess, the adaptability of cemented carbide extends into emerging technologies, including nanomaterials for semiconductor applications. The ongoing research into the characterization and wear performance of cemented carbide reinforces its relevance across various sectors, providing essential solutions that drive innovation and sustainability. As industries seek to improve their operational efficiency, the integration of advanced materials like cemented carbide will undoubtedly shape the future landscape of manufacturing, facilitating the advancement of precision engineering and supporting the development of next-generation technologies.

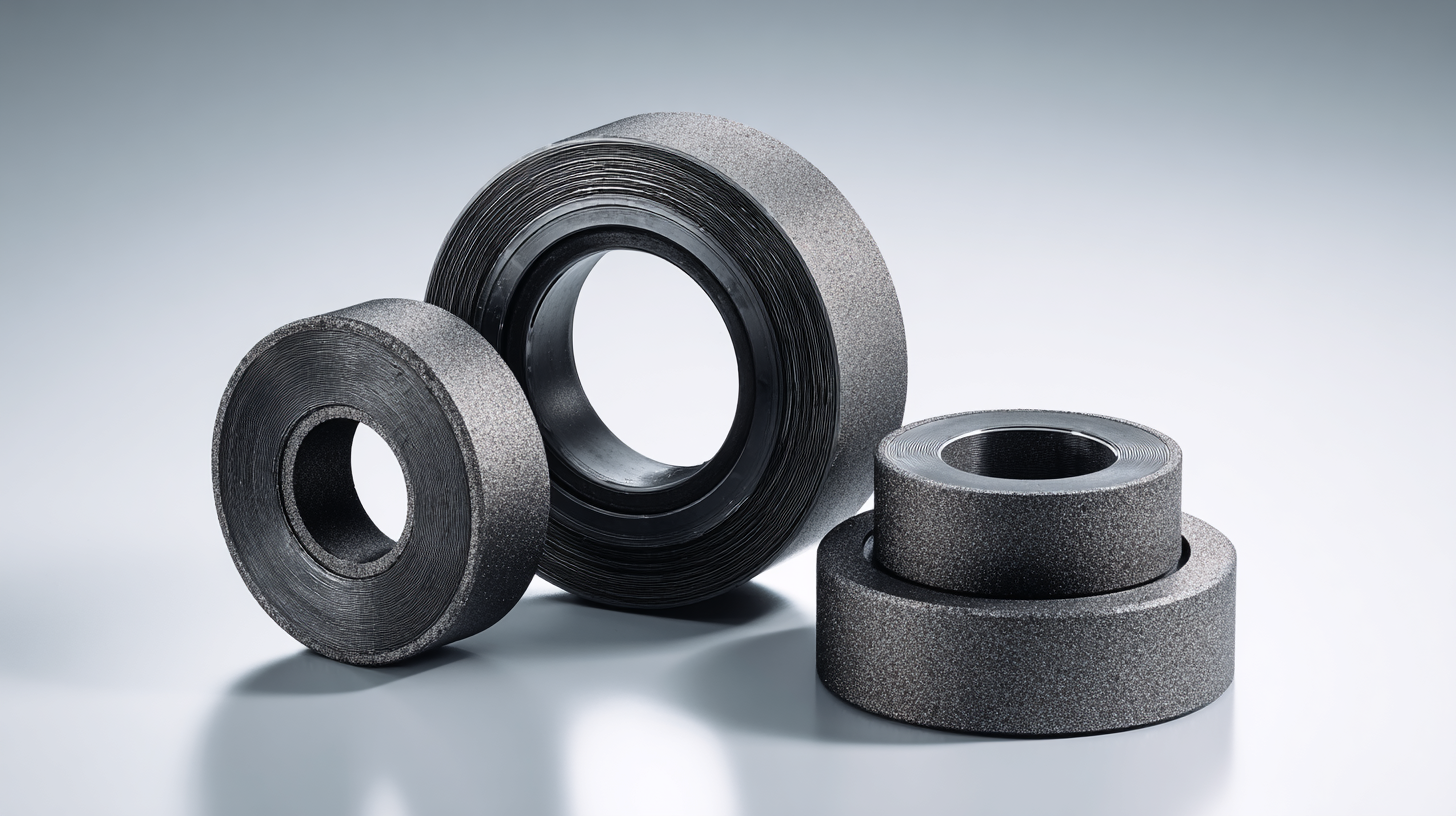

Cemented carbide has revolutionized manufacturing by enhancing tool performance and longevity. With its superior hardness and wear resistance, cemented carbide cutting tools dominate the market, accounting for approximately 77.3% of the total carbide cutting tools market share in 2024. The increasing integration of advanced composite materials in mining tools is expected to boost efficiency and durability, with projections indicating that by 2025, over 60% of these tools will incorporate such innovations. This shift highlights the industry’s commitment to improving operational performance and sustainability.

Cemented carbide has revolutionized manufacturing by enhancing tool performance and longevity. With its superior hardness and wear resistance, cemented carbide cutting tools dominate the market, accounting for approximately 77.3% of the total carbide cutting tools market share in 2024. The increasing integration of advanced composite materials in mining tools is expected to boost efficiency and durability, with projections indicating that by 2025, over 60% of these tools will incorporate such innovations. This shift highlights the industry’s commitment to improving operational performance and sustainability.

The impact of advanced coatings on cemented carbide tools cannot be overstated. Recent research emphasizes the importance of surface engineering, with innovative coatings like CrAlN being pivotal in enhancing cutting tool performance. Additionally, the tungsten carbide market is projected to reach $50.7 billion by 2035, driven by demand from various sectors, including automotive and aerospace, underlining the ongoing evolution in tool technology.

Tips: Consider utilizing advanced cutting fluids and nanofluids to enhance machining performance in turning processes. Ensure proper surface treatment and coating applications to maximize the durability and efficiency of your cemented carbide tools, thereby increasing their operational lifespan.

Cemented carbide, a composite material made from tungsten carbide and a metal binder, has become increasingly vital across various industries due to its exceptional hardness and resistance to wear and tear. The manufacturing sector, in particular, has embraced cemented carbide tools to enhance productivity and reduce downtime. According to a report by MarketsandMarkets, the global cemented carbide market is projected to reach USD 15.31 billion by 2026, highlighting the growing reliance on these materials for efficient production processes. Industries such as automotive, aerospace, and machining benefit significantly from cemented carbide components, which offer improved performance and extend tool life.

Innovatively, cemented carbide is now being utilized in applications that range from mining to oil extraction, where high performance and durability are crucial. In the mining sector, for example, tools made from cemented carbide can last up to 50% longer than traditional materials, resulting in substantial cost savings. A study by Grand View Research indicates that the global mining tools market is expected to surpass USD 32 billion by 2027, with cemented carbide playing a pivotal role in meeting the demands for efficient and resilient drilling equipment. As industries continue to evolve, the versatility and reliability of cemented carbide ensure its place at the forefront of manufacturing advancements.

Cemented carbide has emerged as a game-changer in the realm of manufacturing, particularly when it comes to enhancing efficiency and extending the longevity of tools. Known for its exceptional hardness and wear resistance, cemented carbide provides manufacturers with the perfect solution to meet the demands of high-speed machining processes. By using cemented carbide tools, manufacturers can achieve increased production rates, superior surface finishes, and reduced downtime caused by tool wear.

Tips for Maximizing Manufacturing Efficiency with Cemented Carbide Solutions:

Incorporating cemented carbide into manufacturing processes not only increases efficiency but also fosters a more sustainable approach by reducing waste and conserving resources. As industries continue to evolve, embracing these advanced materials can pave the way for revolutionary changes in manufacturing practices.

Cemented carbide has transformed the manufacturing landscape, thanks to its superior hardness and wear resistance. However, to fully leverage these advantages, maintaining the longevity of tools made from this material is essential. Proper care and showcasing best practices in tool maintenance can significantly enhance their lifespan and performance in various applications.

One effective tip for extending tool longevity is to always ensure that tools are stored in appropriate conditions. Avoid exposing them to moisture or extreme temperatures, which can degrade their effectiveness over time. Regular cleaning after use is crucial as well; utilizing appropriate cleaning agents will help eliminate any build-up of debris or contaminants that can potentially cause premature wear.

Additionally, implementing the right cutting parameters is vital for maintaining tool integrity. Excessive speeds or feed rates can lead to undue stress on the tool, resulting in faster degradation. It’s advisable to experiment with different settings to find the optimal balance that maximizes both efficiency and longevity. Monitoring cutting fluid usage is another key factor; sufficient lubrication reduces friction and heat, prolonging the tool’s life in production settings.