Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

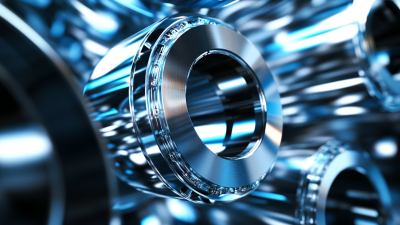

In today's industrial landscape, the selection of the right materials is crucial for ensuring efficiency and durability in manufacturing processes. Tungsten Carbide Brazing Rods have gained significant attention due to their superior wear resistance and high-temperature performance, making them ideal for applications in industries such as aerospace, automotive, and manufacturing. According to a report by Research and Markets, the global tungsten carbide market is expected to reach $2.3 billion by 2025, driven by the growing demand for high-performance cutting tools and wear-resistant materials. As industries seek solutions that enhance productivity and minimize downtime, understanding the nuances of choosing the best Tungsten Carbide Brazing Rod becomes essential. This guide delves into the critical factors to consider when selecting the most suitable rod for your specific industrial needs, ensuring optimal performance and longevity in challenging environments.

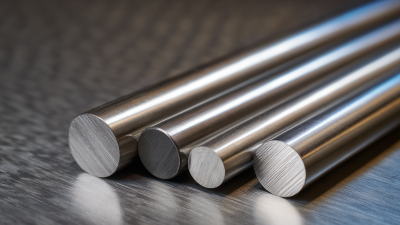

When selecting a tungsten carbide brazing rod for industrial applications, several key factors can significantly influence performance. The composition of the brazing rod is crucial; higher tungsten content generally improves hardness and wear resistance, making it suitable for demanding environments. Additionally, the quality of the manufacturing process can affect the rod's overall reliability. Rods that undergo precision fabrication and rigorous quality control are less likely to fail in critical applications.

Tips for choosing the right tungsten carbide brazing rod include evaluating the specific needs of your application. For high-temperature environments, opt for rods with superior thermal stability. Consider the compatibility of the rod with the base materials you are joining; mismatched thermal expansion rates can lead to structural weaknesses.

Furthermore, examine the rod's diameter and length, as these dimensions can impact the fusion process and the finished joint's integrity.

Understanding the intended application will also help in selecting the appropriate rod. For heavy-duty industrial tasks, prioritize rods designed for high impact resistance. Always consult with suppliers about the performance ratings of their products to ensure you make an informed choice tailored to your operational requirements.

When selecting the best tungsten carbide brazing rod for industrial applications, understanding the specific alloys available is crucial. Tungsten carbide is recognized for its durability and resistance to wear, making it ideal for industries like mining, manufacturing, and aerospace. Different tungsten carbide alloys, such as WC-Co, WC-Ni, and WC-Ta, each offer unique properties suited to particular applications. For instance, WC-Co alloys provide high toughness and are often used in cutting tools, while WC-Ni blends exhibit excellent corrosion resistance, making them suitable for harsh environments.

When selecting the best tungsten carbide brazing rod for industrial applications, understanding the specific alloys available is crucial. Tungsten carbide is recognized for its durability and resistance to wear, making it ideal for industries like mining, manufacturing, and aerospace. Different tungsten carbide alloys, such as WC-Co, WC-Ni, and WC-Ta, each offer unique properties suited to particular applications. For instance, WC-Co alloys provide high toughness and are often used in cutting tools, while WC-Ni blends exhibit excellent corrosion resistance, making them suitable for harsh environments.

Tips: It’s essential to conduct a thorough analysis of the operating conditions, as this will guide the selection of the appropriate alloy. A study by the National Institute for Metalworking Skills highlighted that choosing the right tungsten carbide alloy can improve tool life by up to 30%, significantly reducing operational costs.

Additionally, consider the brazing technique being employed. High-temperature brazing techniques often favor alloys with higher cobalt content for better adhesion and strength at elevated temperatures. The ASM International indicates that proper thermal management can enhance the bond integrity of tungsten carbide pieces by as much as 25%, underscoring the importance of selecting the appropriate brazing rod.

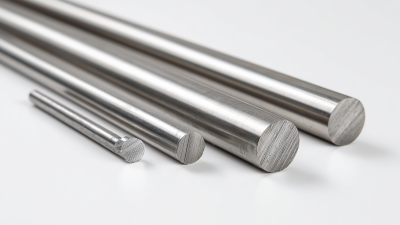

When choosing the best tungsten carbide brazing rod for industrial applications, it is crucial to focus on key metrics that determine durability and performance. The global tungsten market is witnessing significant growth, projected to increase from USD 1.39 billion in 2025 to USD 1.51 billion in 2026, highlighting rising demand for tungsten in various industries, including defense and technology. This growth is propelled by tungsten’s unmatched heat resistance and strength, making it ideal for high-performance applications.

One essential factor to consider is the rod's composition and quality, as these elements directly influence its durability. Tungsten carbide rods are known for their resistance to wear and corrosion, making them suitable for demanding environments. Moreover, with China imposing export restrictions on critical metals, industries must be prepared for potential supply chain disruptions, further underscoring the importance of selecting high-quality brazing rods.

Tips: When selecting a tungsten carbide brazing rod, always check for certifications that guarantee material quality. Additionally, consider sourcing from multiple suppliers to mitigate risks associated with supply chain disruptions. Staying informed about market trends can also ensure you choose products that best align with ongoing industrial demands.

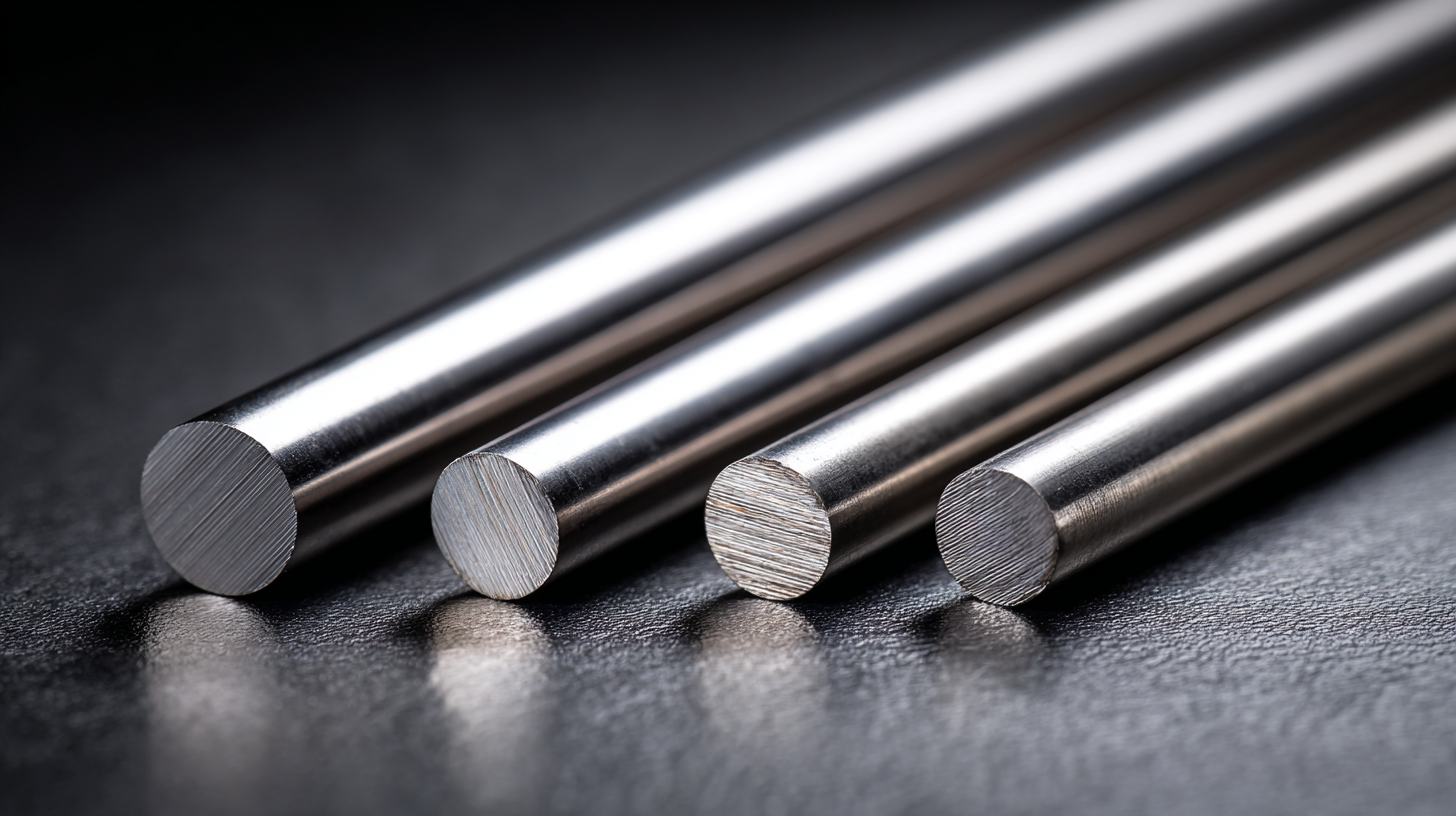

When selecting tungsten carbide brazing rods for industrial applications, understanding the cost-effectiveness of various options on the market is crucial. Recent analysis indicates that high-quality tungsten carbide rods can significantly reduce manufacturing expenses in the long term, even if the initial investment is higher. According to a study published by the International Journal of Advanced Manufacturing Technology, businesses that invest in superior tungsten carbide materials report a decrease in replacement costs by up to 30%, highlighting the importance of considering both upfront and ongoing costs.

Tips: When evaluating different brands of tungsten carbide brazing rods, compare their wear resistance and thermal conductivity, as these factors can directly affect the performance and lifespan of the rods. Additionally, assessing customer reviews and case studies can provide valuable insights into the durability of different products in real-world applications.

Furthermore, it’s essential to consider the welding environment and the specific application requirements. A recent report by the Welding Journal indicates that using the right brazing rod formulation can enhance joint strength and reduce production downtime by as much as 20%. Therefore, thorough research and a keen understanding of market options are vital for making the most cost-effective choice in tungsten carbide brazing rods.

When working in high-temperature environments, selecting the right tungsten carbide brazing rod is crucial for ensuring durability and performance. The best practices for utilizing these rods involve understanding the specific thermal and mechanical demands of your application. High-quality tungsten carbide rods are designed to withstand extreme temperatures and resist wear, making them ideal for brazing superalloys that are often difficult to machine.

Tips for effective use of tungsten carbide brazing rods include maintaining optimal brazing temperatures to avoid overheating, which can weaken the joint. Additionally, employing advanced lubricating and cooling techniques can significantly enhance the machinability of difficult-to-machine alloys, allowing for better heat dissipation and prolonging the life of both the rod and the workpiece.

Furthermore, ensure proper joint design and surface preparation before brazing. A clean surface allows for better adhesion and strength of the brazed joint. By adhering to these practices, you can maximize the performance of tungsten carbide brazing rods in even the most demanding industrial applications.