Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the precision-driven world of machining, selecting the optimal lathe insert is crucial for enhancing productivity and achieving superior surface finishes. Recent industry reports highlight that improper tool choices can lead to a 20% increase in production costs due to tool wear and decreased efficiency. With the global lathe insert market projected to reach $2.1 billion by 2024, understanding the factors influencing insert selection has never been more critical for manufacturers. A carefully chosen lathe insert not only impacts machining accuracy but also directly correlates with tool life and overall operational costs. This article outlines seven essential tips that will guide you in making informed decisions when selecting the right lathe insert tailored to your specific machining needs.

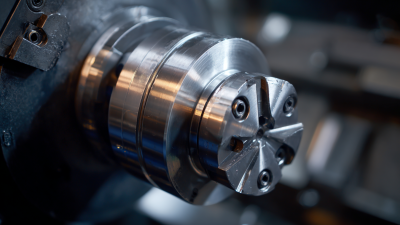

When selecting a lathe insert, understanding the different types is crucial for optimizing machining performance. Lathe inserts are typically categorized by their geometry, coating, and substrate material. A recent report from the Manufacturing Technology Institute indicates that using the right insert can increase tool life by up to 50%, reducing downtime and enhancing efficiency in production environments. For example, positive rake angle inserts are often preferred for softer materials, as they reduce cutting force and improve chip formation, leading to smoother finishes.

In addition to geometry, the coating of lathe inserts plays a significant role in performance. Inserts coated with titanium nitride (TiN) can provide benefits such as improved wear resistance and reduced friction. According to a survey conducted by the Cutting Tool Engineering magazine, 68% of machinists reported enhanced performance and longer tool life when using coated inserts compared to their uncoated counterparts. Understanding the various options available—such as carbide, ceramic, and high-speed steel inserts—enables manufacturers to choose inserts that best suit their specific machining applications and materials, thereby optimizing their overall productivity and effectiveness.

When selecting the right lathe insert for your machining needs, evaluating insert geometry is crucial for achieving optimal cutting efficiency. Different insert geometries can significantly influence the cutting action, tool wear, and the quality of the finished surface. Recent research highlights the fabrication of cutting inserts using chromium-molybdenum high-speed tool steel through material extrusion 3D printing. This technology enables the production of tailored geometries that can enhance tool performance in turning operations, reflecting a growing trend towards customization in insert design.

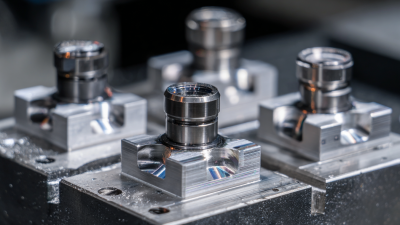

Tips for choosing the right insert geometry include understanding the material characteristics of both the workpiece and the insert itself. For instance, when machining difficult-to-machine alloys, applying advanced cooling and lubrication techniques can improve tool life and surface integrity. The use of coated inserts, like tungsten carbide, has been shown to optimize surface roughness significantly in materials like EN 24 steel, achieving a reduced roughness below 0.4 μm Ra. Additionally, adopting specific chip breaker designs can increase tool life and improve hole integrity, demonstrating how optimizing insert geometry not only enhances cutting efficiency but also contributes to greater overall productivity in machining operations.

When selecting a lathe insert, understanding the workpiece material is critical for achieving optimal machining performance. Different materials, such as steel, aluminum, and composites, require specific insert characteristics to ensure efficient cutting. For instance, if you're working with steel, inserts made from high-speed steel or carbide are ideal due to their durability and heat resistance. In contrast, softer materials like aluminum can be machined with inserts that have a sharper edge and a lower rake angle, allowing for smoother cuts and better surface finishes.

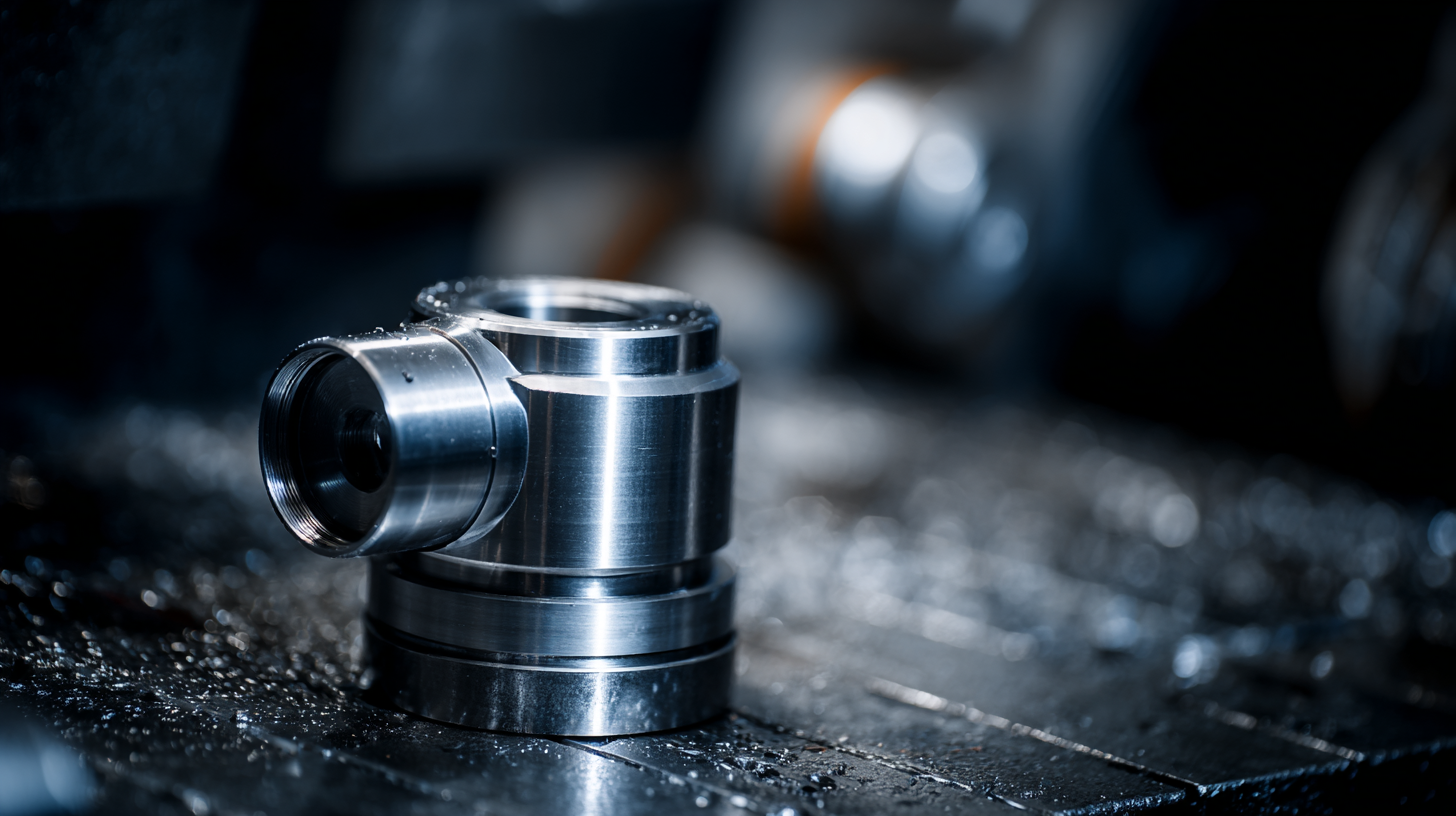

Furthermore, consider the hardness and toughness of the workpiece material as these factors directly influence insert wear rates. For harder materials, using a tougher insert with a thicker coating can prolong tool life, while softer materials can benefit from inserts with a finer edge to enhance precision. Overall, matching the insert material to the workpiece is crucial not only for tool longevity but also for achieving the desired quality in the final product. Understanding the specific machining requirements based on the material will help you make informed decisions that boost productivity and efficiency in your operations.

Selecting the right lathe insert extends beyond geometry and substrate; a crucial factor is the coating applied to the tool. Coatings significantly enhance tool performance by improving wear resistance and reducing friction. According to a recent report by the International Tooling Association, approximately 70% of tool wear can be attributed to friction and thermal effects, which are mitigated by high-quality coatings. Common options such as TiN, TiAlN, and PVD coatings not only prolong tool life but also maintain cutting efficiency, making them invaluable in high-speed machining environments.

For instance, titanium aluminum nitride (TiAlN) coatings can withstand temperatures up to 1000°C, providing exceptional hardness and oxidation resistance. This feature is particularly beneficial when machining materials like stainless steel and titanium alloys, where cutting temperatures soar. In a study published in the Journal of Manufacturing Science, it was reported that using inserts with TiAlN coating led to a 25% increase in tool life compared to uncoated inserts in dry machining applications. Understanding these coating options allows manufacturers to select inserts that align with their specific machining needs, ultimately enhancing productivity and cost-effectiveness.

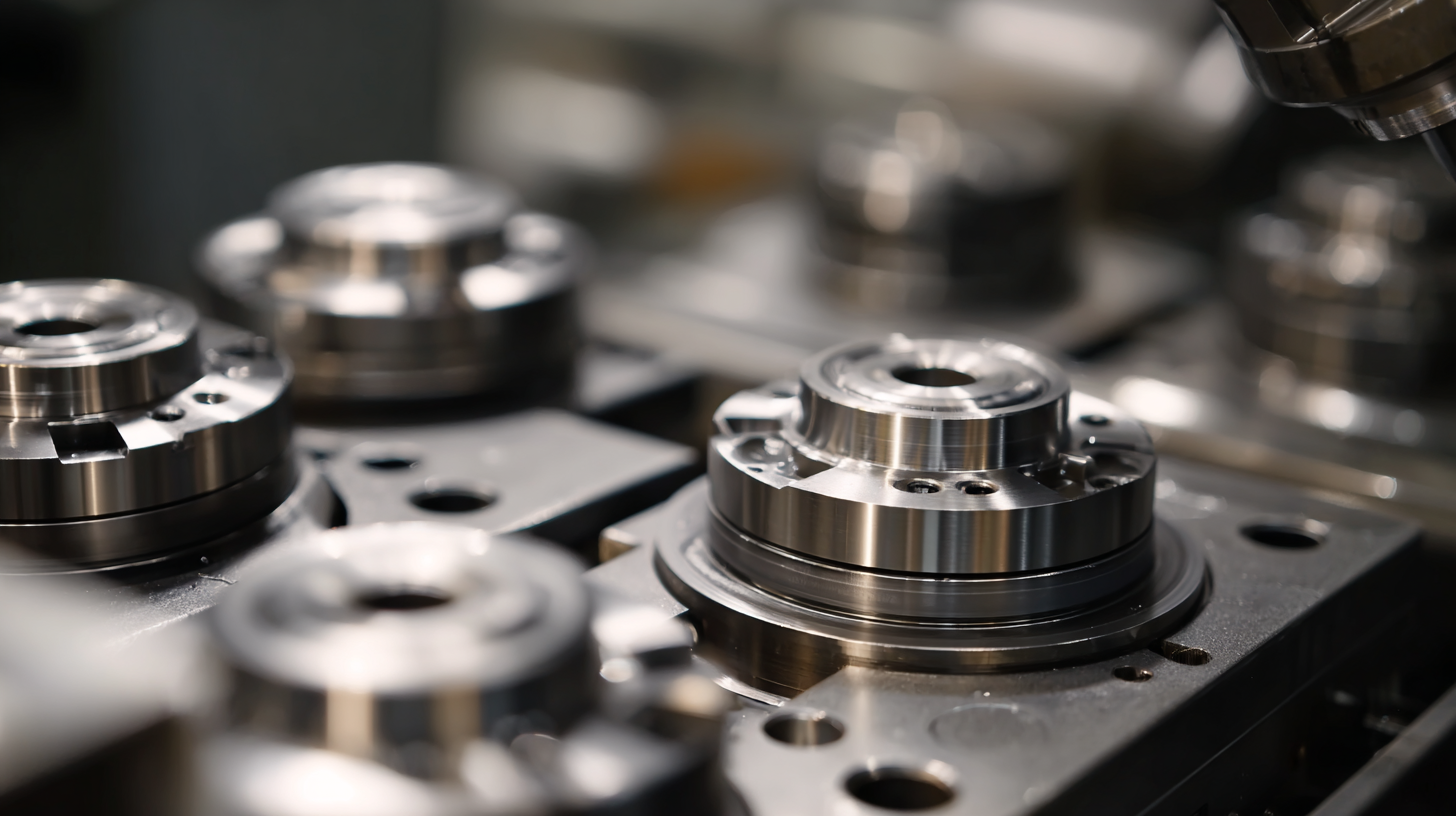

When selecting lathe inserts, the balance between cost and quality is crucial for maximizing machining efficiency and sustainability. According to a report by the American Society of Mechanical Engineers (ASME), the right insert can improve tool life by up to 30% , while inappropriate choices can lead to increased downtime and material waste. This highlights the importance of investing in quality inserts, which often yield better performance, thereby reducing overall production costs in the long run.

A comparative study from the Metalworking Industry Association indicates that, although premium inserts may come with a higher upfront cost, their advanced materials and coatings often result in longer service life and better cutting precision. For instance, carbide inserts show a significant increase in wear resistance and can operate at higher speeds compared to standard steel inserts, offering a compelling return on investment. Thus, organizations must conduct a thorough analysis of their machining requirements, taking into account factors such as materials, cutting conditions, and production volume, to make informed decisions about their insert selection that align with both budget Constraints and performance expectations.