Leave your message now to get your free sample and discount price

Leave your message now to get your free sample and discount price

In the evolving landscape of industrial tools and machining, Tungsten Tipped technologies are at the forefront of precision engineering, promising to revolutionize the way we approach manufacturing and material processing. As industries seek to increase efficiency and reduce costs, the adoption of Tungsten Tipped tools is becoming increasingly significant. These innovative tools leverage the exceptional hardness and durability of tungsten, enabling them to cut through a variety of materials with unparalleled precision. This article delves into the science behind Tungsten Tipped tools, exploring their unique properties, advantages over traditional materials, and the profound impact they are having across different sectors. From improving operational efficiency to enhancing product quality, understanding how to effectively utilize Tungsten Tipped technologies is key for industries aiming to stay competitive in today’s market. Join us as we unpack the science behind these transformative tools and their potential to reshape industrial practices.

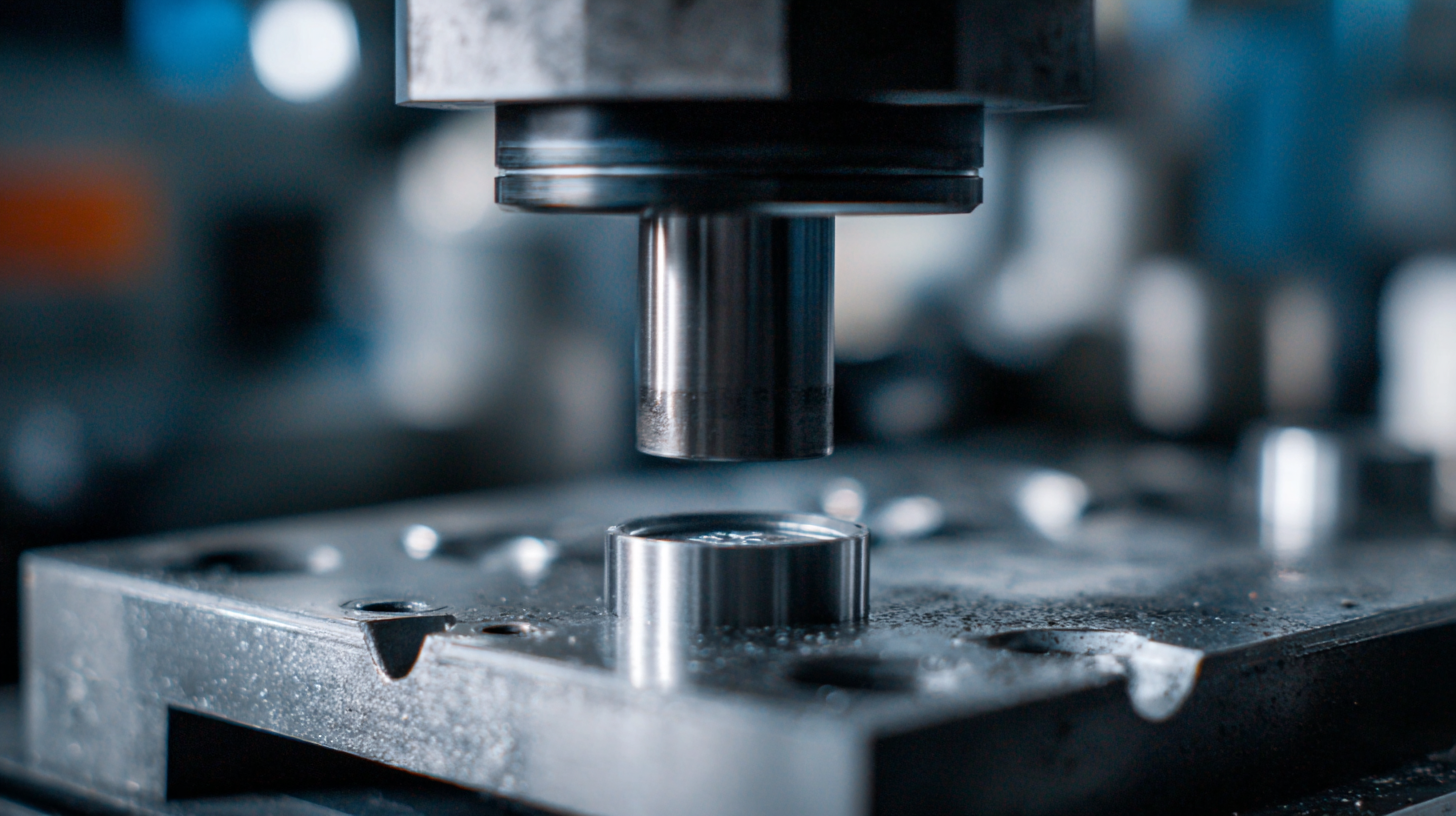

Tungsten tipped tools have emerged as a game-changer in various industries, particularly in manufacturing and construction, due to their unique design features aimed at enhancing precision. One of the key innovations is the highly durable tungsten carbide alloy, which contributes to a significant increase in hardness compared to traditional steel tools. According to a report by the American National Standards Institute (ANSI), tungsten carbide tools can achieve hardness ratings up to 90 HRA, which allows for cleaner cuts and reduced wear during operation.

Additionally, advanced engineering has led to the customized geometry of tungsten tipped tools that optimizes cutting performance. These tools are designed to improve both chip removal and heat dissipation, which minimizes the risk of thermal damage to workpieces. A study by the National Institute of Standards and Technology (NIST) indicated that precision-enhancing features in these tools can improve machining accuracy by up to 30%. As industries continue to prioritize efficiency and quality, the integration of tungsten tipped tools is proving vital for achieving high-performance results and maintaining a competitive edge.

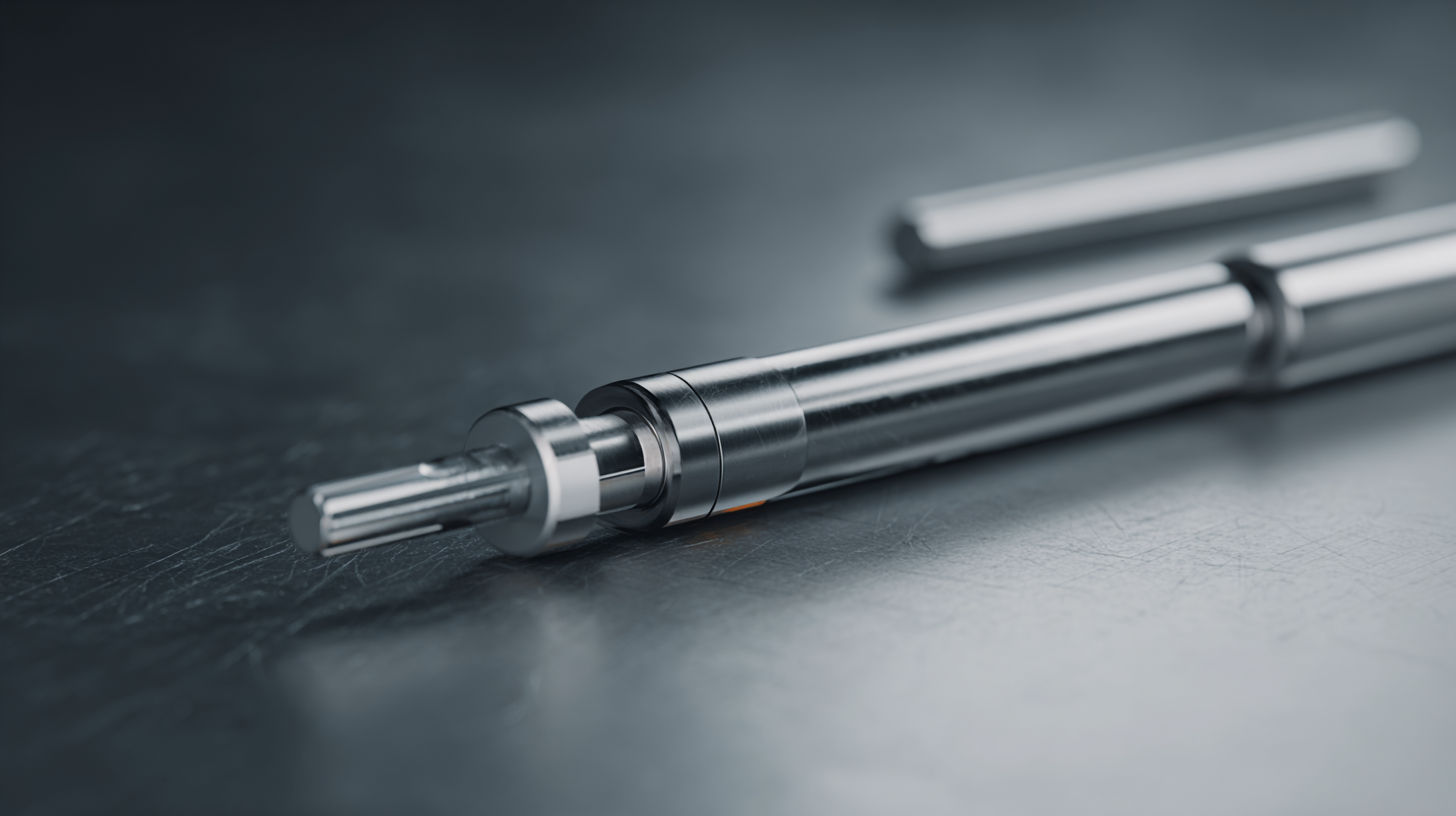

Tungsten-tipped tools have emerged as a game-changer in various industrial applications, thanks to their remarkable durability and performance characteristics. The intrinsic properties of tungsten, particularly its high melting point of 3,422°C (6,192°F), enable the creation of tools that can withstand extreme conditions. According to a report by Market Research Future, the global demand for tungsten tools is projected to grow at a CAGR of approximately 5.7% between 2021 and 2028, driven by their effectiveness in reducing tool wear and enhancing productivity.

The mechanisms behind tungsten’s exceptional performance are primarily attributed to its hardness and tensile strength. Tungsten ranks 9 on the Mohs scale of hardness, which makes it ideal for cutting and drilling applications where wear resistance is critical. Additionally, tungsten's ability to maintain its hardness at high temperatures prevents thermal deformation during extended use, a feature highlighted in a study published in the Journal of Materials Science. This durability translates to lower operational costs, as tools require less frequent replacement, further emphasizing tungsten's role in revolutionizing precision manufacturing across numerous industries.

The advancement of tungsten tipped tools marks a significant shift in the machining industry, distinguishing itself from traditional tool materials such as high-speed steel and carbide. The hardness of tungsten, rated at 8.5-9 on the Mohs scale, allows these tools to maintain sharper edges and resist wear for extended periods. Reports suggest that tungsten tipped tools can last up to three times longer than their high-speed steel counterparts, drastically reducing production downtime and enhancing efficiency. The ability to withstand high temperatures without losing performance further solidifies tungsten's position as a superior choice in precision machining.

When comparing tungsten tipped tools to conventional materials, one notable advantage is their enhanced performance in difficult machining environments. Studies indicate that these tools can increase feed rates by 30-50%, allowing for faster production cycles and reduced operational costs. As industries strive for efficiency, switching to tungsten tipped tools can lead to significant savings on tool wear and replacement costs—essential factors for competitive manufacturing.

**Tips:** When transitioning to tungsten tipped tools, consider conducting trial runs to identify optimal settings and parameters that maximize their efficiency. Additionally, routine maintenance and monitoring of tool condition can further extend the life of your tools, ensuring sustained productivity and precision in your operations.

Advanced manufacturing techniques play a pivotal role in the production of tungsten tipped tools, significantly enhancing their performance and precision. The integration of methods such as additive manufacturing and precision machining allows for intricate designs that were previously unattainable. These techniques enable manufacturers to produce tools with optimized geometries, ensuring better edge retention and superior cutting capabilities. By harnessing advanced technology, it is possible to create tungsten tools that not only meet but exceed the demanding requirements of various industries, from aerospace to automotive.

Moreover, the application of advanced manufacturing techniques also contributes to greater consistency and quality control in tungsten tool production. Automated processes and sophisticated supply chain management reduce the likelihood of defects, ensuring that each tool meets stringent industry standards. This reliability fosters trust among users, encouraging adoption across sectors that necessitate high-performance tools. As the demand for precision continues to rise, the evolution of manufacturing methods will undoubtedly play a crucial role in shaping the future of tungsten tipped tools, pushing the boundaries of what is achievable in precision engineering.

The adoption of tungsten-tipped tools is rapidly growing across various industries, fueling a transformation in manufacturing and production capabilities. As the global carbide tool market is anticipated to rise from $11.54 billion in 2024 to $18.41 billion by 2032, the compound annual growth rate (CAGR) of 6.0% highlights the increasing demand for high-performance tools. Tungsten's properties, such as exceptional hardness and resistance to wear, make it an ideal choice for cutting and drilling applications, enhancing productivity and efficiency.

Tips: When considering the integration of tungsten tools in your operations, evaluate the specific applications where durability and precision are paramount. Investing in high-quality tungsten tools can lead to significant long-term savings by reducing tool replacements and increasing operational efficiency.

The development of China's tungsten industry reflects this trend, as it evolves into a robust industrial system with escalating production and sales revenues. With international trade intensifying, domestic companies are presented with both challenges and opportunities, paving the way for innovative practices and partnerships. Companies can benefit from staying informed about market dynamics and technological advancements to leverage tungsten tools effectively.