0102030405

Comparison between Copper Brazing and Silver Brazing in the Welding of Carbide Rotary Files

2025-04-24

Comparison between Copper Brazing and Silver Brazing in the Welding of Carbide Rotary Files

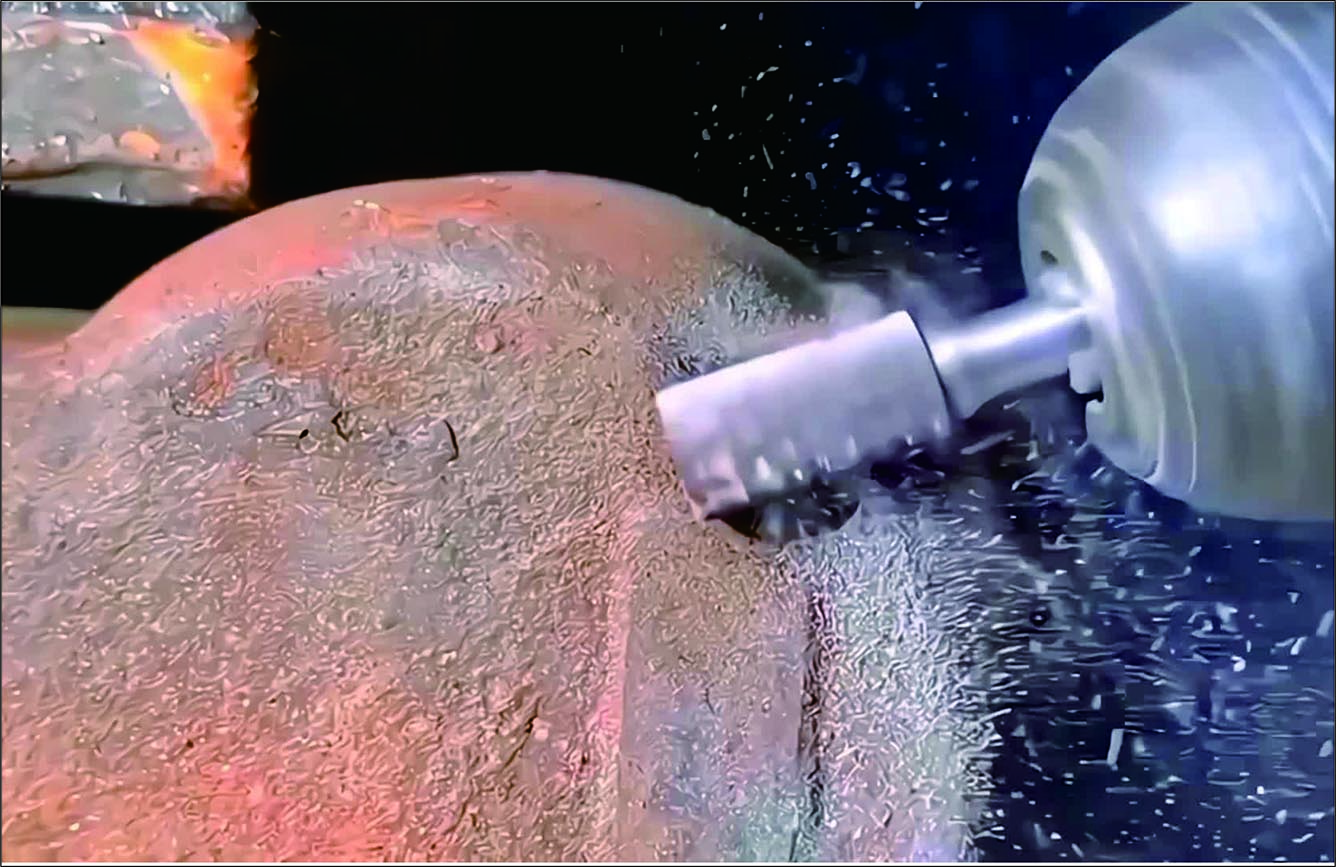

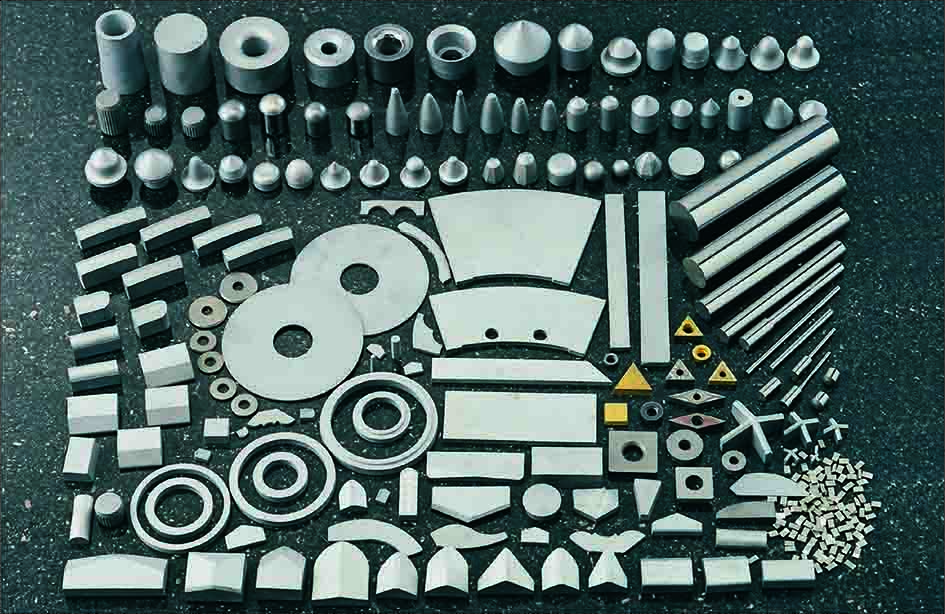

In the manufacturing of carbide rotary files, the welding process directly impacts product quality. As the mainstream processes, copper brazing and silver brazing differ fundamentally in the following six aspects:

1. Welding Material Characteristics

1.1 Copper Brazing

- Filler metal composition: Mainly copper-based alloys (such as pure copper, brass), containing trace elements like zinc and tin

- Cost advantage: The filler metal is inexpensive, approximately 1/5 to 1/3 the cost of silver brazing materials

- Historical application: Originated in the Warring States period, a traditional hard soldering process

1.2 Silver Brazing

- Filler metal composition: Silver-based alloys (silver content 30%-72%), often containing copper, zinc, and cadmium

- Material characteristics: Sandwich structure (surface silver + intermediate copper alloy), combining high electrical conductivity and crack resistance

2. Welding Temperature Requirements

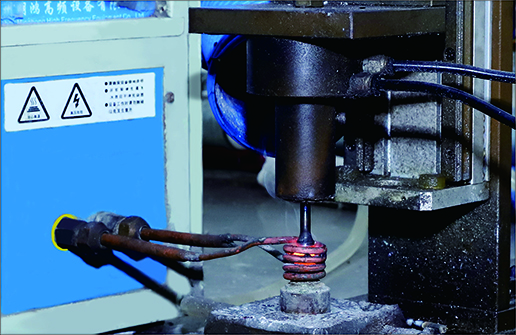

2.1 Copper Brazing

- Temperature range: 1100°C ± 50°C

- Impact on carbide:

- Cobalt element liquefies above 900°C

- Surface oxidation rate increases by 3-5 times

- Metallographic structure deteriorates, hardness decreases by 10-15HRA

2.2 Silver Brazing

- Temperature range: 800°C ± 30°C

- Impact on carbide:

- Below the critical thermal damage temperature of carbide

- Performance retention rate exceeds 95%

3. Welding Stress and Defects

3.1 Copper Brazing

- Stress level: Welding stress reaches 150-200MPa

- Common defects: Micro-crack occurrence rate of 15%-25%, concentrated at the tool tip root

- Cause analysis: High temperature expands the difference in thermal expansion coefficients between the alloy and steel shank (difference up to 40%)

3.2 Silver Brazing

- Stress level: Welding stress < 80MPa

- Defect control: Micro-crack occurrence rate < 5%

- Structural advantage: Sandwich design buffers thermal stress, reducing the thermal expansion coefficient difference to within 15%

4. Welding Strength Performance

4.1 Copper Brazing

- Shear strength (MPa): 180-220

- Fatigue life (cycles): 50,000-80,000

- High-temperature lasting strength: 40% strength reduction at 600°C

4.2 Silver Brazing

- Shear strength (MPa): 280-320

- Fatigue life (cycles): 150,000-200,000

- High-temperature lasting strength: 15% strength reduction at 600°C

5. Comprehensive Selection Recommendations

- Decision model:

- Cost priority + general performance → Choose copper brazing (cost reduced by 30%-50%)

- Performance priority + high reliability → Choose silver brazing (service life extended by 2-3 times)

- Special requirements:

- High-frequency welding needed → Prioritize silver brazing (efficiency increased by 40%)

- Environmental requirements → Select cadmium-free silver brazing materials (compliant with RoHS standards)

Through the above comparative dimensions, manufacturers of carbide rotary burrs can scientifically select welding processes according to product positioning (economy/high-end), processing precision requirements (below IT10 grade/above IT8 grade), and customer budgets to balance performance and cost.